Our Technology and Expertise

By controlling interfacial interactions and structures at the molecular level to achieve desired surface properties:

- Controlling Surface Properties of Post-consumer Wastes: Transforming post-consumer wastes into valuable reinforced fillers (Learn more…)

- Controlling Interfaces between Natural Materials and Silicone: Nature materials as reinforced fillers or crosslinkers for sustainable silicone (Learn more…)

- Controlling Elastomer Interfaces: High wettable and low non-specific protein absorption surfaces of silicone elastomer. (Learn more...)

- Controlling Mineral Interfaces, particularly derived from silica, for utilization as biosensors, chromatographic monoliths and as reinforcing fillers (Learn more…).

Contract Services

We offer contract services for interfacial silane and silicone materials that of hydrophilic surface modification for your customer-defined devices; sustainable silicones using natural materials; and silicone elastomers that can benefit from unusual fillers.

Transforming Post-consumer Wastes into Valuable Reinforced Fillers

Save Cost, Reduce Carbon Footprint

There is a growing global trend toward transforming materials from renewable sources or post-consumer waste in line with the principles of sustainability and the circular economy. By modifying the surfaces of waste materials, upcycled waste can be made compatible with silicone, enabling it to act as reinforcing fillers. This approach not only reduces costs but also lowers the carbon footprint of silicone-based materials.

Selected Publications:

- Dissolving Used Rubber Tires, (Green Chemistry, 2020, 22, 94 – 102).

- Cleaning steel by devulcanizing rubber from used automotive tires (RSC Sustain., 2023, 1, 2006-2013)

- Naked Alpaca Wool is a Better Reinforcment for Silicone Elastomers, (Green Chemistry 2021, 23 (19), 7692-7700)

[top]

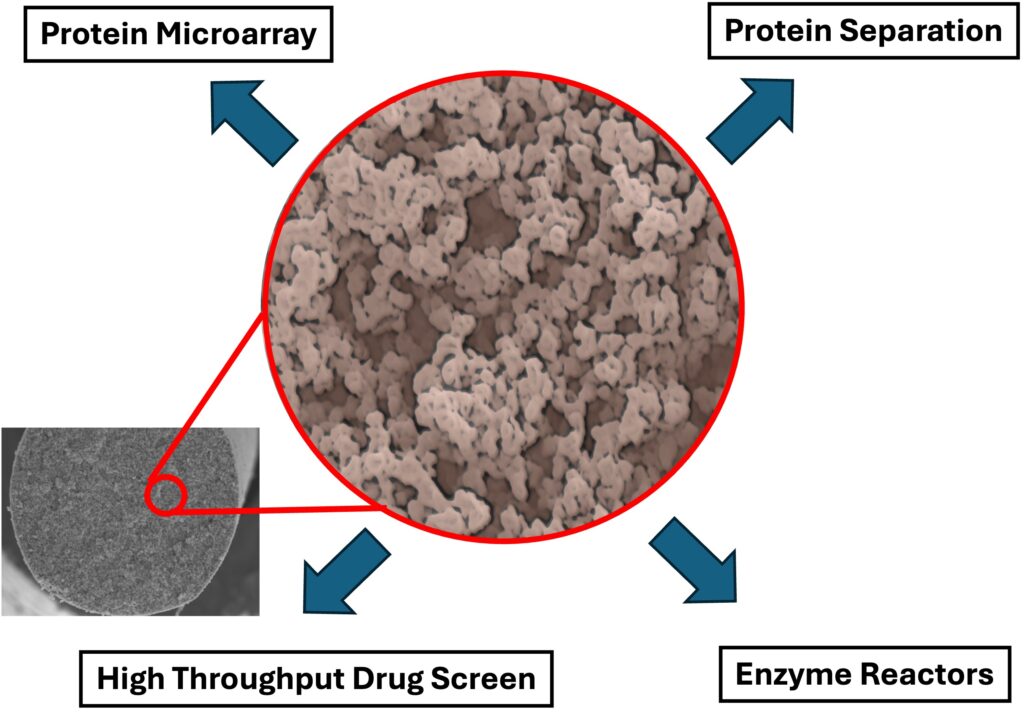

Controlling Mineral Interfaces

Controlling Mineral Interfaces, particularly derived from silica, for utilization as biosensors, chromatographic monoliths and as reinforcing fillers.

Selected Publications:

- A Facile Phenylboronate Modification of Silica by a Silaneboronate, (Langmuir, 2013, 29 (2), 594-598)

- Silica Shell / Gold Core Nanoparticles: Correlating Shell Thickness with the Plasmonic Red Shift upon Aggregation. (ACS Applied Materials & Interfaces, 2011, 3, 3942–3947)

- Immobilization of bacteriophages on modified silica particles. (Biomaterials 2010, 31, 1904-1910)

- Non-destructive horseradish peroxidase immobilization in porous silica nanoparticles. (Journal of Materials Chemistry, 2007, 17, 4854 – 4863)

- Ultrasensitive ATP Detection Using Firefly Luciferase Entrapped in Sugar-Modified Sol-Gel Derived Silica. (J. Am. Chem. Soc. 2004, 126, 6878-6879)

- Sugar-Modified Silanes: Precursors for Silica Monoliths. (J. Mater. Chem. 2004, 14, 1469 – 1479)

[top]

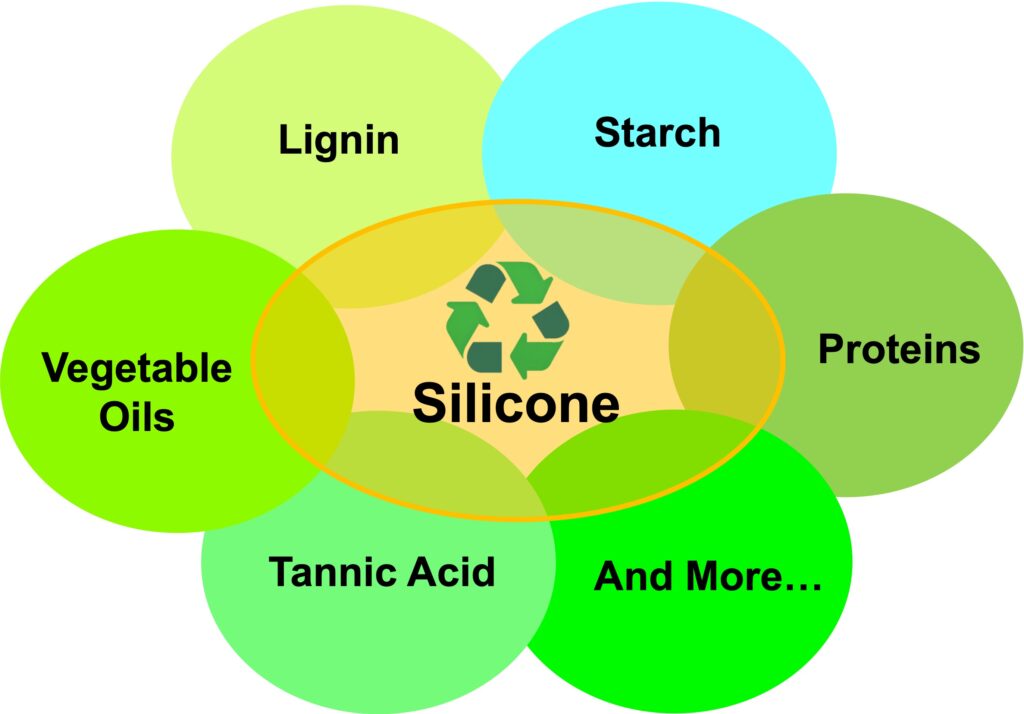

Controlling Interfaces between Natural Materials and Silicone/Silica

Nature provides many different products that can serve as starting materials for silicones: lipids, proteins, antioxidants, including vitamins, and saccharides. Some of these can simply act as diluents that should improve degradation in the environment. More interesting is the ability to deliver new function to silicones, including antioxidant properties, artificial enzymes and more force responsive, thermoplastic elastomers based on sugar.

Nature provides many different products that can serve as starting materials for silicones: lipids, proteins, antioxidants, including vitamins, and saccharides. Some of these can simply act as diluents that should improve degradation in the environment. More interesting is the ability to deliver new function to silicones, including antioxidant properties, artificial enzymes and more force responsive, thermoplastic elastomers based on sugar.

Selected Publications:

- Silicone structurants for soybean oil: foams, elastomers, and candles. (ACS Sustainable Chem. Eng. 2019, 7, 1, 1347–1352)

- Acrylated Soybean oil: A key intermediate for more sustainable elastomeric materials from silicones. (Green Chem., 2023, 25,

280) - Delivery of both active enzyme and bleach from water-in-silicone oil (D4) emulsions. (Langmuir 2007, 23, 3620-3625)

- Antioxidant Silicone Oils from Natural Antioxidants. (Green Chem. 2022, 24, 8751 – 8759)

- Hemin-doped, Ionically Crosslinked Silicone Elastomers with Peroxidase-like Reactivity. (Adv. Funct. Mater. 2021, 31 (52), 2105453)

- Energy‐Dissipating Polymeric Silicone Surfactants. (Rapid Macromolecular Communications 2020, 41 (11), 2000161)

- Starch/Silicone Elastomers and Foams. (Sustainability 2023, 15(13), 9941)

[top]

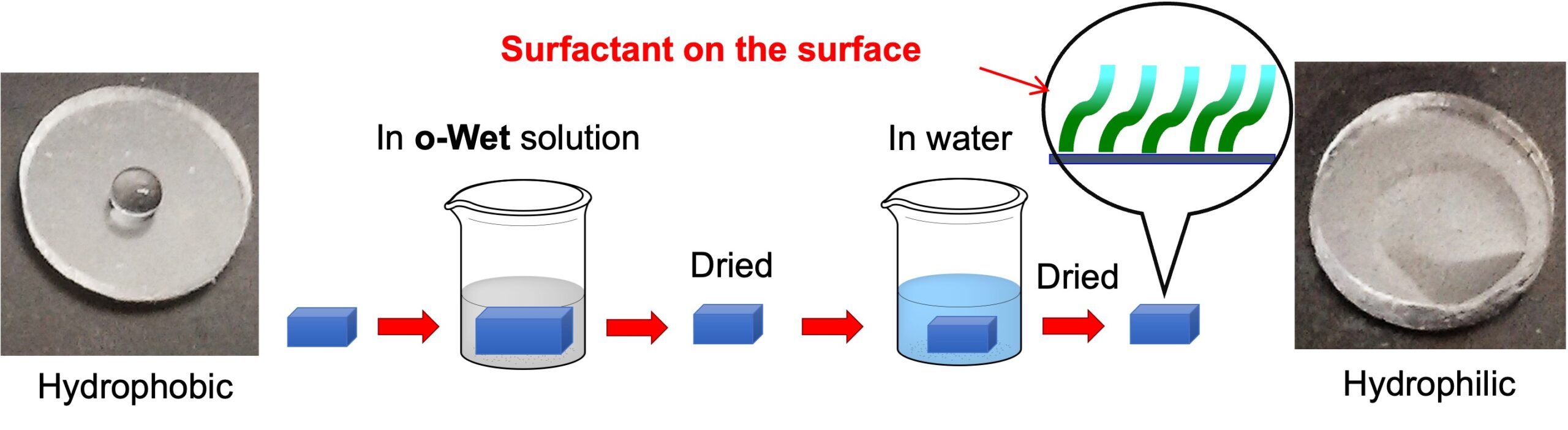

Controlling Elastomer Interfaces

Our proprietary technology renders standard silicone elastomers highly water wettable (contact angles 10° to 20°) during or after device fabrication in a simple and straightforward manner. The surfaces are resistant to fouling, including by biological entities, and can be made additionally functional.

Surface modification:

Hydrophilic silicone blend:

![]()

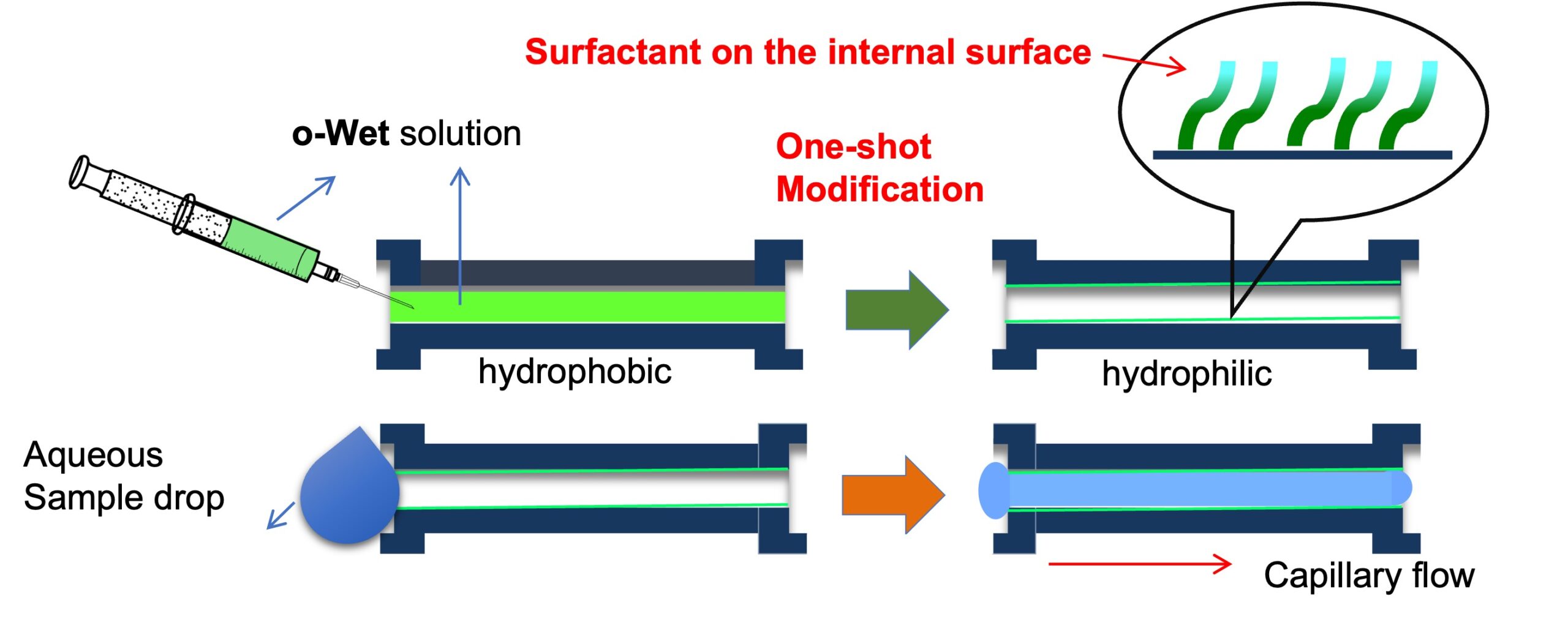

Application case 1

After the desired complex multichannel device was formed, o-Wet was applied to the channels. After rinsing, the material remains on the surfaces (Scheme 1), and capillary forces drive spontaneous water flow along the channels. No pumping is required; even gravity is sufficient to allow the water to drain (click the videos below to see the performances).

Scheme 1:

[top]